Why Duinkop Coco?

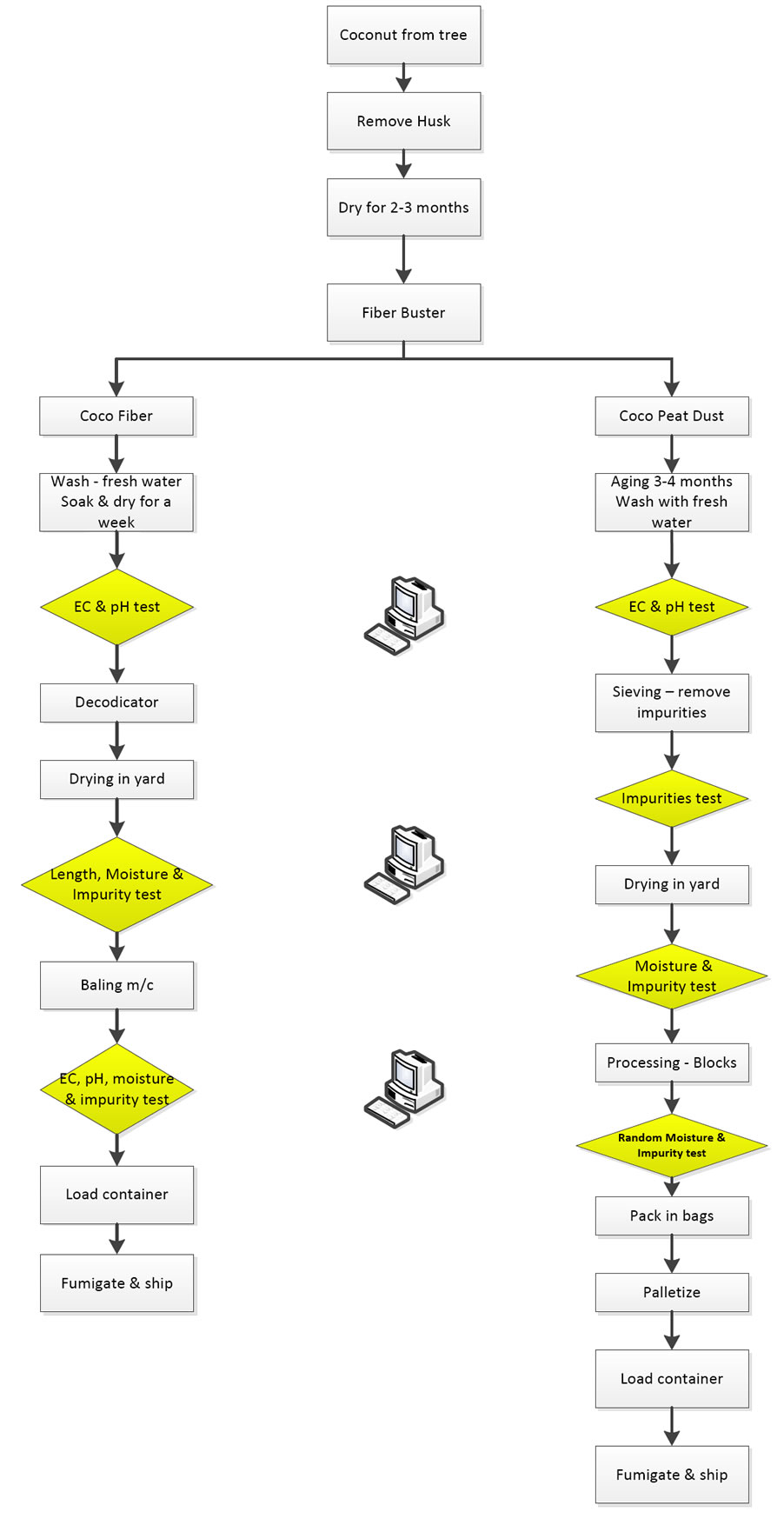

We are one of the few companies who can be termed as vertically integrated with coconut farms to fiber mills and peat manufacturing. We can confidently say that the entire process is under our watchful eyes.

Will raw material quality affect the end product?

We at Duinkop have massive atmospheric bunkers to store the raw material in a clean weed free environment. In addition to these we have our own fiber mills (Varun Fibers) supplying the raw-material to the bunkers which gives us complete process control. While most of our competitors store the material in open fields prone to weeds, pests apart from having no knowledge about the raw material source.

Will there be a physical difference between cocos?

By storing in bunkers at our factory, the material undergoes aging process only after which it is taken for further processing. Only during the aging process does the coco peat become more mature & physically stable, which is of great importance to growers. Unfortunately some manufacturers process the material in fresh form (due to lack of storage space) which ultimately results in poor stability and decompose pre-maturely.

Does location of factory make a difference?

Coco peat manufacturers located in the coastal area face a unique problem. The trees can easily tolerate and absorb potassium, sodium and chloride. Unlike most plants that are cultivated in the horticultural sector, these salts have no negative impact on palm trees. In case of horticultural plants the salt content is detrimental to the root growth of the plant. Since our factory and plantation is located far from the coast our coco material is significantly low in salt. Due to fresh water availability in the location, even these are maintained to the minimum and supplied to the grower (clients) who have less head-ache.

Why pay premium for coco peat?

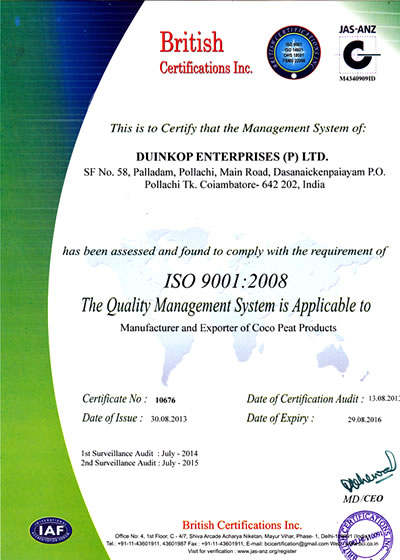

Quality comes at a cost. Apart from Duinkop being an ISO 9001 company, the production process is regularly monitored by external RHP audits. These audits & feedback make our company a better facility to work with every passing year. Each of our container samples are stored in our lab for 6 months to monitor any weed issues. Since the coco peat sector is still highly unorganized, procuring material at cheaper prices from sub-standard location could result in huge problems for a grower.

Dealing with the middleman?

We would like to demarcate ourselves from the “fly by night operators” that do business with flashy web-sites & with no real connection with the manufacturers of the product.

We invite potential clients to visit our factory and have a firsthand look of our operation to support our argument “what makes us the best”